After owning 63 ICE (Internal Combustion Engine) Bikes my first Electric Bike. The 2018 Zero DSR with Charge Tank.

woensdag 9 september 2020

dinsdag 30 juni 2020

INDIAN 741 SCOUT 500CC 2 CYL

My Uncle bought an Indian Motorcycle just after the 2nd World War.

He bought it from a Military Dump Store for 550 Dutch Guilders, with is about 250 Euro’s nowadays.

Matching numbers: Frame number 741 15151, Engine Number GDA 15151.

They were made

from 1941 -1944

741 GDA101-up, 741101-up, Military 741(b)

lightweight 30.50ci

All Export 741's GDA101 & up were supplied with

blackout lighting as standard.

I wonder if this

bike is still “alive” If somebody has seen this bike just let me know please…..

As World War II

loomed, the United States military set about drawing up specifications for a

useful, universal motorcycle, and put its construction out for bid.

But though

several manufacturers submitted bids, ultimately designed and manufactured

motorcycles to sell, there’s little doubt that the US Military preferred

Harley-Davidson’s WLA to any other brand or style of motorcycle in the WWII

era.

Offering several

machines based on production bikes, Indian tried to compete but initially

without much success.

The sales

success came when Indian offered the 741 based on the civilian Thirty-Fifty

model.

The US Army favored

the 45 cubic inches of the WLA Harley-Davidson, and this Indian was but 30.5

cubic inches, or 500cc.

However, the

little twin proved to be very durable and reliable and ultimately some 35,000

were produced, mainly for the Allies.

Incidentally, Harley riders in the

military had difficulty with the Indian’s foot clutch operated with the heel;

Harley’s required the toe.

Engine

performance is about 15 HP at 4,800 rpm. Ignition is by battery and coil, (the

B in the model designation points to battery /coil ignition) weight is 450 lb.,

top speed 65 mph.

Transmission is

3 speed hand shift, tires 3.50 x 18.

After the war

many thousands of these sturdy machines became available for civilian use and

they were subsequently dressed up in civilian guise.

vrijdag 22 mei 2020

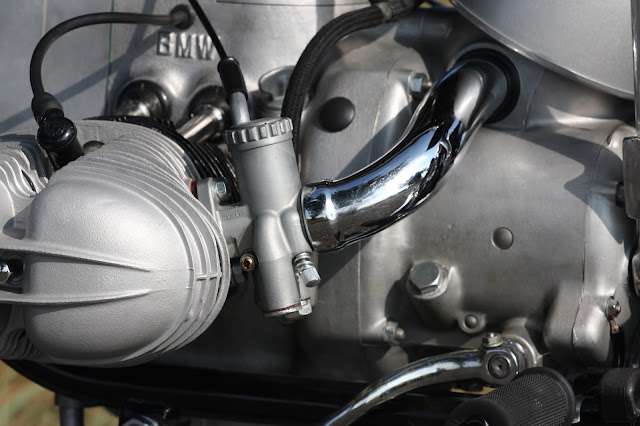

BMW R69S 1968

BMW R69S 1968

After I owned a BMW R60/2 I

was looking for a BMW

/2 conversion, preferably a R/2 frame with a R75 engine.

I had already

seen several, but if you are looking for such a bike, you cannot find one.

Several bikes in

parts but they were all missing the sheet metal parts.

On my search I

came across this beautiful R69S.

It had only 2

owners since 29-03-1968 when it first hit the road.

The motorcycle

was made on 07-09-1966 and delivered to the Dutch importer Hart Nibbrig &

Greeve N.V. in Sassenheim on the 15-09-1966

The first owner

had it in his possession for 13 years and the 2nd owner, a very nice lady, for

31 years until 2012, after which the motorcycle ended up in storage.

For some time

the motorcycle got restored by Harry Meijer

on behalf of Theo Terwel who did all

the paint work.

It got some

beautiful aluminum rims, a “Schorsch

Meier” Tank and a 12 Volt Alternator

Conversion Kit.

Carburetor:

The original 6v generator delivers

60 watts it was replaced by a 12v alternator witch delivers 200 watts.

This system does not affect

the (Bosch magneto) ignition system that came standard on the /2

So you will be able to run

the engine on one cylinder for tuning.

After the first run fuel was

dripping out of the idle mix screw.

It turned out to be one of

the brass floats was cracked.

Cracking of the floats

results in the floats taking in fuel and becoming heavier and that caused the

overflow.

I replaced them with plastic

(7 gram) floats.

500 Km service:

I Replaced all the fluids.

For the Engine I use Castrol

Classic XL30.

For the transmission, drive

shaft and final drive I use Millers oils Classic Gear Oil 80w90 GL 4

Carburetor:

One cable adjusting screw

was completely in and the other completely out and still the bike was not

running smooth.

I found out that there were

2 different Throttle cables, one from a R51/2-R68 and one from a R50/5.

For sure, that doesn’t work.

I will replace them with the

original parts.

Gearbox:

Downshifting from 4 to 3 and

3 to 2 was sometimes a problem.

At times it would pop out of

gear.

My first thought was that it

needed a proper run in because the gearbox was overhauled.

If one carefully inspects

the shift lever it seems to have been designed for the pin to go in from the

top. A review of my old books and photos

show it both ways. I suspect that BMW

designed it to go in from the top, the logical way. A close look at the lever shows that it has a

“flat” where one would expect the nut and washer to go. Later they found that a certain percentage

wouldn’t stay in gear due to the lever hitting the exhaust pipe. Rather than redesign the lever they just

switched the pin and solved the problem. (DuaneAusherman)

Labels:

BMW 1968,

BMW R69 S,

BMW R69S,

BMW R69S 1968,

R69S

zondag 1 maart 2020

BMW SLASH 2 CONVERSION R50-R69S 750-1000cc Engine

A Basic Guideline to Building a 1955 – 1969 BMW R50-R69S Conversion

Background

I like to restore and work

on motorcycles.

Not only make them like new

but also improve them but keep their original look as much as possible.

Some of the bikes I worked

on before:

For the next project I would

like to restore a BMW slash 2

Looking for modifications I

came across this article from Brock Downey.

A great help if you are

going to do a project like this.

For many years numerous BMW

riders have modified their pre-1970 BMW’s to except post 1969 components.

This involves minor frame

modifications and a transplant of the engine, transmission, electrical

components and various smaller items.

Personal taste influenced by

available …. has prevailed.

When completed correctly,

the finished product is very satisfying and if cared for will give many years

of trouble free service.

The following are a number

of reasons to initiate building a conversion

·

Currently owned

machine is too expensive to repair to regain limited power out put

·

Availability of

parts is greater for post 1989 motorcycles

·

Increased power

for sidecar use or to meet today’s better paved roads with a solo machine

·

The owner simply

wants the reliability of a newer powertrain and electrical system, combined

with the classic vintage appearance

Note: ideally this

modification should not be undertaken with pre 1970 machines with matching

serial numbers, that are affordable candidates for restauration to their

original condition.

These bikes should be sold

or traded to collectors or restorers.

As a point of interest, a

conversion still requires the same level of restauration of a stock bike.

Swingarm, wheel and steering

bearings, shocks and springs, brakes shoes and brake drums, spokes, rims, tires

and tubes all must be in a good to excellent condition.

The idea of building a

conversion is not to build a “bearer” that pogo sticks down the road in a

dangerous fashion and doesn’t stop well just because the builder is trying to

save a few bucks.

Conversions are actually as

expensive as stock restorations.

This is important to know

before starting.

Dreams and drawing board

Before starting it is

important to take time to discuss the following:

·

What do I want

to use the bike for – solo or sidecar

·

How much am I

willing to spend

·

When completed,

will it be a day-to-day rider or am I going to pull out all the stops and start

with a powder coated frame and finish with newly painted body parts

·

Who is a good

contact to talk with that has successfully completed a conversion, or is

mechanically knowledgeable to help and identify to pros and cons of variety of

options available before and during this project

·

Do I have access

to local painters, plating, machine and mechanical shops

·

Should I

advertise to purchase an already completed Conversion

Thinking out loud

In the early 1960’s BMW

upgraded there frames with additional bracing.

This is easily distinguished

by looking to see if the lower steering race is braced.

These frames are arguably

more suited for a conversion, yet earlier frames without the additional bracing

can also be used successfully.

The first items you will

need are obviously a pre-1970 machine and a willing post 1969 donor bike or a

good parts resource.

A complete 1970’s parts

machine may be the least expensive choice.

If you can locate one that

is mechanically sound and inexpensive, it may benefit to purchase it and later

sell off the remaining parts you do not require and off set the initial

purchase price.

Engines from 1978 and prior

are the preferred choice for the Earles fork Conversions, due to the shorter

engine design.

The later boxer engines will

fit the telescopic fork Conversions without the concern for fork clearance.

Good candidates include 750,

900 and 1000cc engines.

The 500 and 600cc engines

will also improve reliability, yet may seem as underpowered as the original

engines.

The 750-1000cc engine share

the same camshaft, therefor you can change/upgrade the cylinders, pistons,

heads and carburetors to gain the larger displacement.

The 500 and 600cc engines

share the same camshaft and can seem a little off in the event the camshaft is

not upgraded to install the 750-1000cc series components.

Staying with the same range

of displacement will allow for a minimal amount of difficulty when

changing/upgrading top end components.

There are a number of

cautions concerning items such as flywheel bolt size and cylinder sleeve to

block clearance when trying to upgrade some of the /5 series engines to later

components.

This article is not intended

to go into that level of detail.

The Project

…………………………. soon, I am still

searching …………….

If you know something just

let me know ……………………..

Labels:

/2 Conversion,

BMW /2 Conversion,

BMW Conversion,

BMW R75/2,

BMW R90/2,

R100/2,

R75/2,

R90/2

Abonneren op:

Reacties (Atom)