BMW R69S 1968

After I owned a BMW R60/2 I

was looking for a BMW

/2 conversion, preferably a R/2 frame with a R75 engine.

I had already

seen several, but if you are looking for such a bike, you cannot find one.

Several bikes in

parts but they were all missing the sheet metal parts.

On my search I

came across this beautiful R69S.

It had only 2

owners since 29-03-1968 when it first hit the road.

The motorcycle

was made on 07-09-1966 and delivered to the Dutch importer Hart Nibbrig &

Greeve N.V. in Sassenheim on the 15-09-1966

The first owner

had it in his possession for 13 years and the 2nd owner, a very nice lady, for

31 years until 2012, after which the motorcycle ended up in storage.

For some time

the motorcycle got restored by Harry Meijer

on behalf of Theo Terwel who did all

the paint work.

It got some

beautiful aluminum rims, a “Schorsch

Meier” Tank and a 12 Volt Alternator

Conversion Kit.

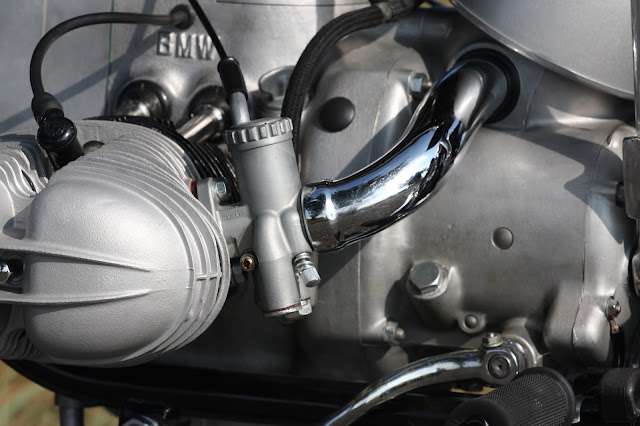

Carburetor:

The original 6v generator delivers

60 watts it was replaced by a 12v alternator witch delivers 200 watts.

This system does not affect

the (Bosch magneto) ignition system that came standard on the /2

So you will be able to run

the engine on one cylinder for tuning.

After the first run fuel was

dripping out of the idle mix screw.

It turned out to be one of

the brass floats was cracked.

Cracking of the floats

results in the floats taking in fuel and becoming heavier and that caused the

overflow.

I replaced them with plastic

(7 gram) floats.

500 Km service:

I Replaced all the fluids.

For the Engine I use Castrol

Classic XL30.

For the transmission, drive

shaft and final drive I use Millers oils Classic Gear Oil 80w90 GL 4

Carburetor:

One cable adjusting screw

was completely in and the other completely out and still the bike was not

running smooth.

I found out that there were

2 different Throttle cables, one from a R51/2-R68 and one from a R50/5.

For sure, that doesn’t work.

I will replace them with the

original parts.

Gearbox:

Downshifting from 4 to 3 and

3 to 2 was sometimes a problem.

At times it would pop out of

gear.

My first thought was that it

needed a proper run in because the gearbox was overhauled.

If one carefully inspects

the shift lever it seems to have been designed for the pin to go in from the

top. A review of my old books and photos

show it both ways. I suspect that BMW

designed it to go in from the top, the logical way. A close look at the lever shows that it has a

“flat” where one would expect the nut and washer to go. Later they found that a certain percentage

wouldn’t stay in gear due to the lever hitting the exhaust pipe. Rather than redesign the lever they just

switched the pin and solved the problem. (DuaneAusherman)